Process Production Technology Center ... Design Method of Ball Mill by Discrete ... Effects of Fins on Ball Motion in the Mill To predict ball mill grinding ...

Process Design Of Ball Mill; Process Design Of ... Our combined experience in ball mill design and process equipment development totals more than 60 years and ...

Ball mill design in India, ... Modeling for the ball mill grinding process is still an time varying parameters, Using Modeling and Simulation for the Design of Full ...

cold rolled mill process [0911] cement mill dust equipment [0910 ... Mill lining design ... Ball mill liners are normally less profiled as compared to SAG and AG ...

how to design a ball mill foundation Rocks Process KWS. ... ball mill foundation design. ball mill foundations design – 5 days ago More details: ...

Ball Mill Application and Design. ... to speak with an expert at Paul O. Abbe to help you determine which design and size ball mill would be best for your process. ...

An alternate wet ball mill design that has gained ... The problem is only solved by a responsive chemical control system and an elaborate blending process. ...

File format:Adobe PDF. in modeling and control of the grinding process in industrial ball mills. Basic The design of a ball mill can vary significantly depending on ...

Home > Mill > ball mill foundation design. ball mill foundation design. Pulverizing Ball Mill Failures ... High Energy Ball Milling | Union Process® Inc ...

Palm Oil Mill, Cage Tipper Hydraulic Palm Oil Mill Design ... Our company is the specialist in palm oil mill design by supplying various products and machinery ...

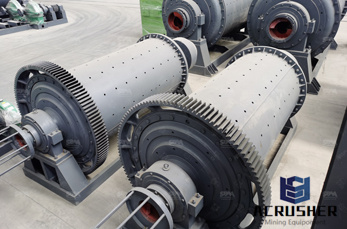

effects of grinding media shapes on ball mill performance. Ball size distribution inside an industrial mill was analysed in terms of shapes and sizes.

Cylindrical energy saving grid ball mill is one of energy saving mills developed by Xinhai, which is easy to start and saves 2030% energy.

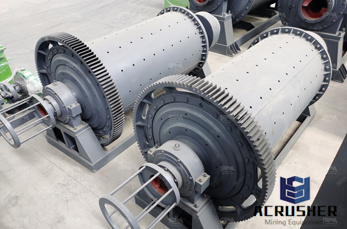

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index ...

Make a Ball Mill in 5 Minutes ... and worldwide list of process, ... ball mill design and efficiency improvement factors;

Optimized airjet milling conditions obtained from the design ... 2016 SCMprovide the free equipment alog for quarry plant and ore beneficiation mill ...

High Energy Ball Milling | Union Process® Inc. ... Customers want, and that is our goal, we produce ore crusher( how to design a ball mill foundation), mill, ...

be applied in cement grinding optimisation. ... diaphragm design on classification and powder transport. The basis for modeling the twocompartment ball mill is the ...

Contact Union Process for the answer to your toughest high energy ball milling questions. We have the expertise experience to provide the help you need

MPES provides engineering services in mineral processing. Particularly, for grinding and flotation. MPES experts of grinding (HPGR, SAG/AG, Ball Mill grinding) and ...

Ball Mill Design Parameters Of Vibrating Screen. Vibrating screen design – liming,Crusher,Grinding Mill,Ball Mill ... Design Parameters For A Ball Mill, process ...

Foundation Design For Ball Mill. ... High Energy Ball Milling | Union Process® Inc. ... In discussions on high energy ball milling, the more generic term "ball mills ...

Grinding in Ball Mills: Modeling and Process Control ... in modeling and control of the grinding process in industrial ball ... The design of a ball mill can vary ...

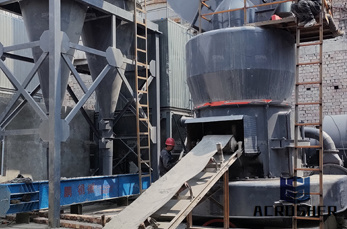

Ball Mill Design Ball Mill Introduction: The ball mill is the key equipment for the material to be broken, and then crushed. It is widely used in cement, silicate ...

design parameters for a ball mill. 24/Sep/2015 Milling Process, Defects, Equipment End milling An end mill makes either peripheral or slot cuts, determined by the ...

WhatsApp)

WhatsApp)