ACHIEVEMENT OF HIGH ENERGY EFFICIENCY IN GRINDING MILLS AT SANTA RITA *S. Latchireddi1 and, E. Faria2 1OUTOTEC (USA) .

Know More ... Energy Saving Ball Mill wasitprovinceinfo Energy Saving Ball Mill, grid ball mill is lined grooved ring plate which increases the contact surface of ...

Keywords: Grinding, mill media, high energy mills, industrial minerals, precious metals. ... outlet of the mill and the grinding process cannot be continued

Our Jet Mill powder grinder is better than any ... increase output with the Jet OMizer. ... This process is a continuous flow and size reduction is almost ...

The electrical energy consumed in the cement making process is in order of 110 ... be applied in cement grinding optimisation. ... grinding balls from leaving the mill.

Grinding energy and physical properties of chopped and hammermilled barley, ... Hammer mill Grinding energy ... important step in the conversion process.

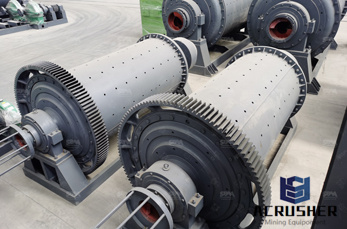

A ball mill is a type of grinder used to grind and blend materials ... Highenergy ball ... Ball mills are used extensively in the mechanical alloying process ...

The Emax is an entirely new type of ball mill for high energy milling. ... the high energy input is effectively used for the grinding process without overheating the ...

Buy flash dryers, air classifier mill, micronization equipment here ... Fluid Energy, recognized as a ... grinding and jet milling operations to produce a ...

Nov 04, 2009· Sweco VibroEnergy Grinding Mill/Deburer Model DM20

52 the milling process takes place during rotation as a result of the transfer of kinetic energy of the moving grinding media into the grinding product.

These can be related to the Hukki relationship between particle size and the energy required to break ... mills in a grinding process. Like ball mills, grinding ...

Energy Mill Gym shipley, Shipley, Bradford, United Kingdom. 2,342 likes · 16 talking about this · 3,363 were here. Energy Mill gym Shipley is a brand new...

Ball Mill,Ball Mills,Ball Mill Machine,Ball Grinding Mill, Ball mill, an energy ... makabsworg Constrained model predictive control in ball mill grinding process 1 ...

The Energy Mill provides a clean, affordable source of alternative energy that will help you save and quit fossil fuels for good. Call us at for more.

William Boulton specialises in the manufacture of vibratory process plant, which covers the complete range of vibratory/gyratory equipment. Call us on 01782 816

Paper mills are a tangible example of winwin opportunities with energy efficiency. There''s cost reduction, emissions reduction and job preservation

ENVIRONMENTAL FOOTPRINT COMPARISON TOOL ... EFFECTS OF DECREASED WATER USE ON ENERGY USE Energy Use at Mills ... Saving process energy in the papermaking industry.

SWECO VibroEnergy Grinding Mills are the most versatile line of mills available today for fast, lowcost particle size reduction to submicron range.

Stirred Grinding Mill Development and Appliion Expansion Graham Davey Process Manager Contents Current ... Xinhai grinding mill has excellent energy saving ...

energy mill grinder process, . Application of Energysaving Ball Mill: Energysaving ball mill is the key equipment for grinding after the crushing process, .

Micronizer ® Jet Mill. ... the introduction of heat or wear into the grinding process and is capable of ... more sizes and options than any other fluid energy mill.

The High Energy Ball Mill Emax is an ... used for the grinding process without ... the grinding time. The high energy .

Austrian Energy Grinding Mills; ... The process engineers at Fluid Energy recognize that no one jet mill is suitable for all powder processing ...

WhatsApp)

WhatsApp)