about « crusher made Depending on our national patent machines such as XZM ultrafine mill, MTM ... mangan bijih flotasi · bateman hamer mill to crush coal · cmc ...

coal plant mill ... Air swept coal mill is the main equipment in cement plant for both drying and grinding of the powders Compared with the ordinary ball mill, ...

Small size, big energy savings 2 Proven technology Today the airswept vertical roller mill is the standard solution for coal grinding installations.

AirSwept coal mill is ideal equipment for coal preparation and widely used in industries including cement, power generation, metallurgy industry, chemical industry, etc.

According to the company a cement plant NSP kiln of supporting the preheater and coal mill system, it has happened so many times grinding head on fire...

The Storm Approach to Coal Pulverizer Optimization ... to as the mill capacity. We prefer to discuss coal throughput as one of the three major components

Coal Mill and Coal Feeders Download as PDF File (.pdf), Text File (.txt) or view presentation slides online.

diagram of coal mill in power plant. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any ...

Chaeng Vertical Roller Mill has simple process, compact structure, product fineness of 80μmR 3%, with steady and average product fineness. Application : Cement Plant ...

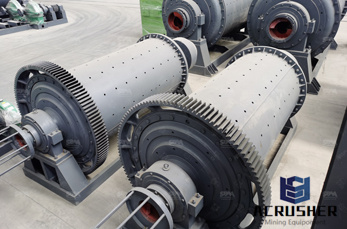

Coal ball mill is the equipment used for grinding and drying coal with different hardness. It is mainly composed of feeding device, principal axis, rotating part ...

Nov 04, 2016· Video embedded· Now chatting: Contact Us: cement ball mill capacity calculationcement ball mill ...

Coal pulverizing in power stations. Pulverizing coal consists in grinding coal as fine as possible prior to combustion in the steamgenerating furnaces of fossil fuel ...

slide 1: Process introduction The coal mill can be divided into low speed coal mill medium speed coal mill and high speed coal mill.

how 2 now mill 2 kelometer. how 2 now mill 2 kelometer. Home > Mining Plants > how 2 now mill 2 kelometer. Mill Valley, California how to grind dried lignite coal ...

Coal mill is the equipment used for grinding and drying coal with different hardness and it is mainly composed of feeding device, principal axis, rotating part ...

In coalfired power plants coal mills are used to pulverize and dry to coal before it is blown into the power plant furnace.

An extremely compact, airswept vertical roller mill, the ATOX coal mill grinds and dries all types of coal. Download our brochure!

coal mill reject works | worldcrushers. Posts Tagged: Coal Mill. how does a coal mill reject system works. February 2007 Archives – MetaFilter Bill O''Reilly does a ...

consumption of coal in coal mill | Solution for ore mining. liming coal crusher and coal mill is the best coal processing machine in the power . Coal Crusher|Coal ...

Coal mill is an important auxiliary equipment for coalpowder furnace, it has three methods to crush the coal lump and grind them into powder,it is crushing,...

A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for ...

Combustion Engineering 783RP BowlMill Coal Pulverizer. enclosed chamber with wear resistant plates. The hammers impact on the coal, crushing it against the plates.

Mill Motor Removal/Replace; PA ... Our skilled technicians have the power and expertise to handle everything from preventative maintenance to major coal pulverizer ...

coal pulveriser maintenance performance. enhancement through the application of a combination of new technologies gerhard holtshauzen a dissertation submitted in ...

WhatsApp)

WhatsApp)